The project aims to study how humidity influences biopolymer materials and explore a passive mechanisms to amplify these effects, making subtle environmental changes visible.

Fiber Reformation Prototype 1_Grid

Irreversible transition_shape change

Create a 4x4 wool yarn grid, shape it while wet, and let it air dry for 5 hours to stiffen.

The grid deformed after the humidity level increased

Fiber Reformation Prototype 2_Strings

Irreversible transition_shape change

Strings with preformed spiral shapes deform as humidity levels increase.

Customized yarn winder produces yarn with a higher TPM (turns per meter) which is more responsive towards humidity changes.

Fiber Reformation Prototype 3_Rotation

Reversible transition_length change

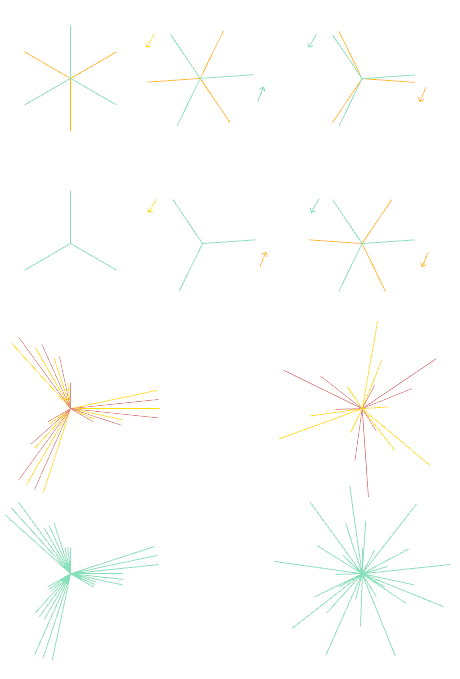

Pattern Exploration

Translate the 2% length change during the fiber deformation process into rotational movement.

Experiment with yarn wrap directions (clockwise and counterclockwise) to change the direction of rotation and create different patterns.

Experiment with yarn wrap directions (clockwise and counterclockwise) to change the direction of rotation and create different patterns.

Detials of pivot

Wrap yarn around pivots with different dierctions

17% to 100% humidity ; Duration: 4k30fps/2s interval

100% to 17% humidity ; Duration: 4k30fps/16s interval

The final installation translates subtle length changes into rotational movement by using extended music wire and a reverse-wrapped yarn method, creating patterns that amplify the subtle movement.

Machine: Laser Cutter, 3D Printer

Material: Metal Wire, Wool Yarn, PETG, Acrylic Board

Sensor: Adafruit AHT20 - Temperature & Humidity Sensor